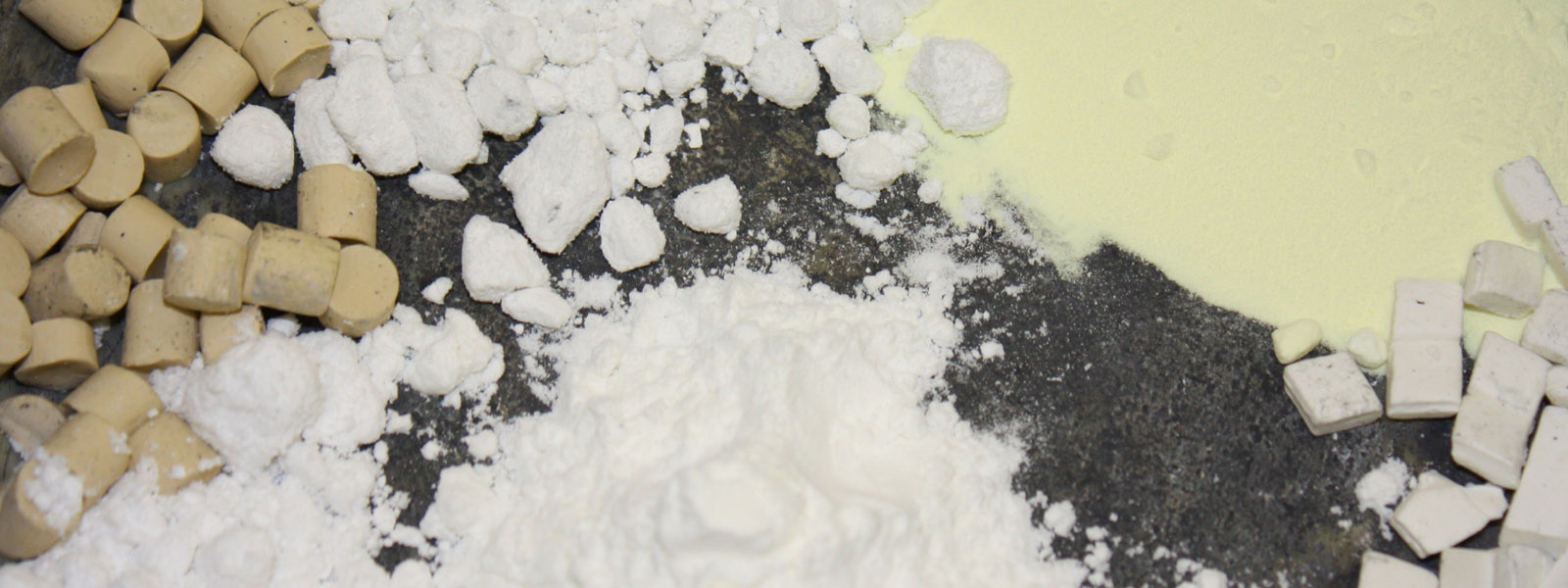

Material Development

Working together to develop your specific rubber and plastic needs.

Lavelle is a rubber material development specialist. With over 2,000 active rubber and plastic formulations, we offer an extensive selection of materials to meet a wide variety of molding needs. And if one of our existing compounds does not meet your specifications or color requirements, we have on-site chemists who can design a new compound that fulfills your specifications.

Butyl Rubber (IIR)

Butyl rubber is a synthetic rubber comprised of a copolymer of isobutylene with a lesser amount isoprene.

Chloroprene Rubber (CR)

Chloroprene, commonly known as Neoprene®, was originally developed as an oil resistant synthetic rubber with a similar molecular structure to that of natural rubber.

Ethylene Acrylic Rubber (EAM)

Ethylene Acrylic rubber is a copolymer of ethylene and methyl acrylate with a small amount of carboxylic acid.

Ethylene-Propylene Diene (EPDM)

EPDM Rubber is a synthetic rubber with very good performance utilized in a wide range of applications.

Fluorocarbon Rubber (FKM)

Fluorocarbon Rubber is a specialized compound with excellent high heat, oil resistance and low compression set.

Hydrogenated Nitrile (HNBR)

Hydrogenated Nitrile is made by selective hydrogenation of the NBR butadiene groups. HNBR is recognized for its strong physical strength for long term exposure to heat, oil and chemicals, as well as, cost effectiveness.

Natural Rubber (NR)

Natural rubber is an elastic latex material harvested from Hevea and Ficus trees.

Nitrile (NBR, Buna N)

Nitrile rubber (NBR, Buna N) is a family of unsaturated copolymers of butadiene and acrylonitrile monomers.

Polyurethane Rubber (AU/EU)

Polyurethane rubber is a versatile material that provides the elasticity of rubber with the strength of metal and ceramic.

Silicone Rubber (VMQ)

Silicone rubber is an inorganic synthetic elastomer that is vulcanized creating a cross-linked silicon based polymer that is reinforced with fillers.

Styrene-Butadiene Rubber (SBR)

Styrene-butadiene rubber is a family of synthetic rubbers derived from the monomers styrene and butadiene.